Water Level Controller

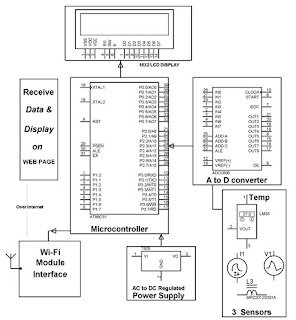

This article explains you how to detect and control the water level in an overhead tank or any other container. This water level controller system monitors the water level of the tank and automatically switches ON the motor when ever tank is empty. The motor is switched OFF when the overhead tank or container is FULL. Here the water level of the tank is indicated on LCD (Liquid crystal Display). Using this system, we can avoid the overflow of the water. We have already seen How water level indicator circuit works using AVR Microcontroller in the earlier post. But, here we are designing the circuit which is used to detect and control the water level automatically in overhead tank using 8051 microcontroller.

In this system water sensing can be done by using a set of 4 wires which are placed at different levels in tank. DC supply probe is placed at the base of the tank.

Water Level Controller using 8051 Circuit Principle:

This system mainly works on a principle that “water conducts electricity”. The four wires which are dipped into the tank will indicate the different water levels. Based on the outputs of these wires, microcontroller displays water level on LCD as well as controls the motor.

Taking quality as our motto, we are engaged in manufacturing and supplying Automatic Water Level Controller. Our given range of water level controllers is acclaimed in the industry for their attributes. This water level controller is made up of finest material & leading edge technology. The offered water level controller is properly examined on different parameters of quality in order to make certain their quality. Our customers can take these water level controllers from us at nominal rates.